- Kot Abdul Malik, Motorway Interchange, Iqbal Town Lahore

- 0300-6186363

PEB (Pre-engineered Building System)

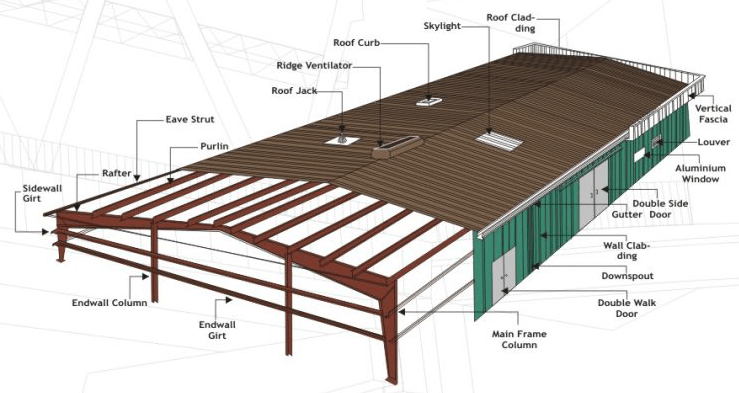

Pre-engineered building is a steel structure built over a structural concept of primary members, secondary members, and the cover sheeting connected to each other. The structural members are custom designed to be lighter in weight as well as high in strength. For today and in the future, Steel has become the material of choice in building construction, compared to concrete and timber. Thus steel building designs have become more flexible, durable and adaptable.

Pre Engineered Steel Buildings (PEB) revolutionized the construction market using built-ups in place of conventional Hot Rolled Sections. PEB is a steel structure built over a structural concept of primary members, secondary members, and the cover sheeting connected to each other. The structural members are custom designed to be lighter in weight as well as high in strength. Pre-Engineered Steel Buildings can be fitted with different structural additions like trusses, mezzanine floors, fascia's, canopies and crane systems as per user requirements.

Pre-engineered buildings are ideal for use in nonresidential, wide span low rise buildings. Among the advantages of PEB is low cost, consistent quality control, and fast delivery to name a few. PEB buildings are used for diverse applications such as factories, warehouses, Marquees, shopping malls, Farms, hospitals, community buildings and several more. Pre-engineered building consists of following components:

1. Structural System

Structural systems are the main load carrying and support members of a pre-engineered building. The shape and size vary based on application and requirements.

2. Secondary System

Secondary members are load carrying members suitable to ensure the stability of the building against forces in any direction. They primarily include purlins and girts, eave strut, cable bracing and open steel web joists.

3. Cladding

MİM Pre-Engineeing construction's pre-painted sheeting is a multi-layer coating system to ensure long life and optimum coating adherence. The steel substrate is hot dipped galvanized zinc or hot dipped zinc / aluminum coated. The surface of the metal coatings is then given a series of pre-treatments to ensure that they are completely clean. CWC's claddings can be used for roofs and walls and are available with or without insulation.

4. Accessories

In addition to the main building components, MIM Pre-Engineeing provides a wide range of building accessories.

Applications of PEB System:

- Warehouse

- Dairy Farms

- Roof Systems

- Generator Rooms

- Logistic Centers

- Car Parking

- Factory Buildings/Halls

- Agricultural Buildings

- Education Buildings

- Sports Building

- Animal Yards

- Agri Malls

- Super Stores

- Poultry Farms Canopies

- Production Halls

- Air Craft Hangers

- Show Rooms

- Petrol/Gas Stations

- Lean To

- Workshops

- Marquee / Event Halls

- Boiler & Coal Sheds

- Cold Stores

Advantages of PEB System:

- Low Initial Cost

- Fast Project Construction

- Architectural Flexibility

- Highest Eave Heights

- Inherent Resistance to Earthquake

- Energy Efficient

- Single Source Responsibility

- Multi-Color Options

- Superior Design Quality

- Low Maintenance/Operating Costs

- Large Clear Span

- Infinite Layout Choices

- Easy to Extension

- Re Locate Able

- Easy to Future Modifications

- Re-sale Options

The PEB system offers multiple advantages to the end-user; the most notable are low initial investment, fast construction time, low maintenance cost, large clear spans, infinite choice of layouts, inherent resistance to earthquakes, ease of expansion and unique attractive appearance.

PEB System is since long a standard in commercial and industrial market segments such as warehouses, distribution centers and industrial facilities are continuing to make greater inroads into the low-rise sophisticated building market. Commercial office buildings and mixed use facilities.

Institutional and governmental constructions are some of the areas where PEB building systems are being used more and more. These buildings are increasingly recognized as reliable, aesthetically pleasing, energy efficient and cost-effective building alternatives.

The sustainable green attributes of metal building systems with their recycled content and recycle-ability makes them a natural choice for today's building owners and specifies.